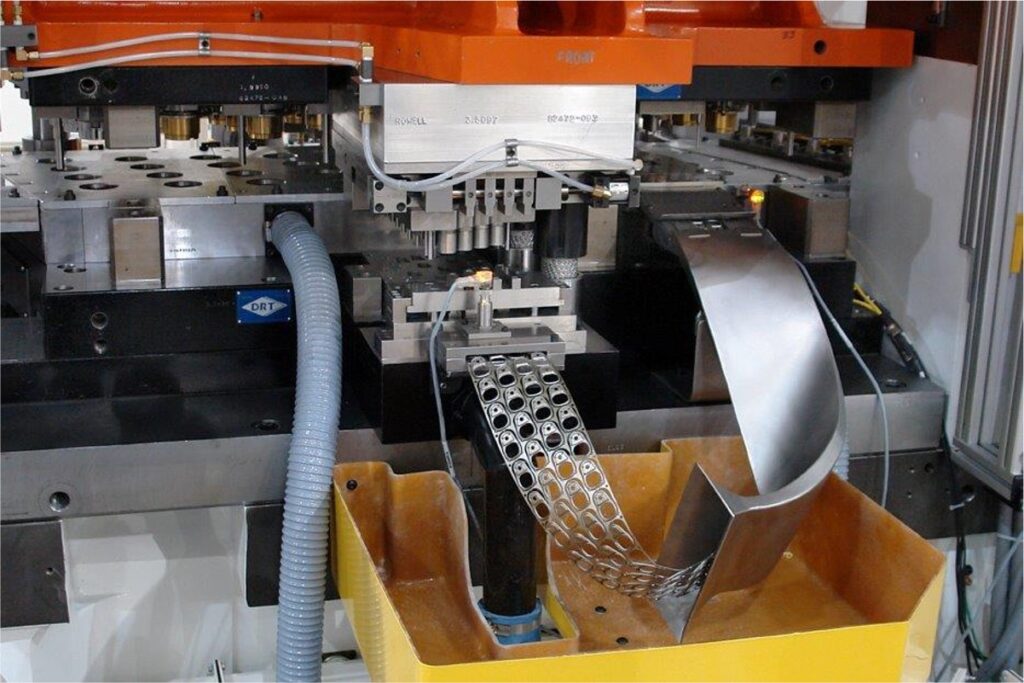

With the broadest and most versatile line of can end systems in the industry, DRT offers high-capacity, flexible easy-open conversion systems for all of your food and beverage manufacturing requirements. From high-output to shorter production runs we have a system that will address your production demands.

The DRT Vision Quad System is a high-volume, 4-out system that will deliver up to 3000 EPM JCAT91, JCAT91R, or SRP875 ends per minute. The Vision Quad incorporates a non-metallic transfer belt to eliminate production downtime caused by belt failure and Ferguson tab feeders for ease of use and setup. The Vision Quad can easily convert the current Triple T beverage systems to this more productive platform.

For superior tab design and efficient system performance, the DRT Vision Food offers 2-out, 3-out, and 4-out capability and a capacity of up to 2000 EPM. The highly efficient Vision Food is ideal for high-volume applications and is equipped with the Sankyo self-compensating tensioner power transmission system. DRT Vision Food is available with 786D, D1500, flatback, D1300, two-finger tabs in steel or aluminum tabstocks.

The DRT Vision I is the ultimate in flexibility with simple, low-cost changeovers, designed for both beer/beverage and food pull panels. Ideal for manufacturers that require simplicity, short runs, and quick changeovers to minimize conversion costs and reduce production downtime. Users can produce stay-on-tab ends, ring-pull tab ends, and full panel pull ends – all in one system. DRT Vision I is available with 786D, D1500, flatback, CAT102, CAT99, two-finger, D1300 tabs, in either steel or aluminum tab materials.

Customers benefit from the research and development conducted by DRT to maintain the lowest food and beverage tab costs in the industry.